A higher level

of control.

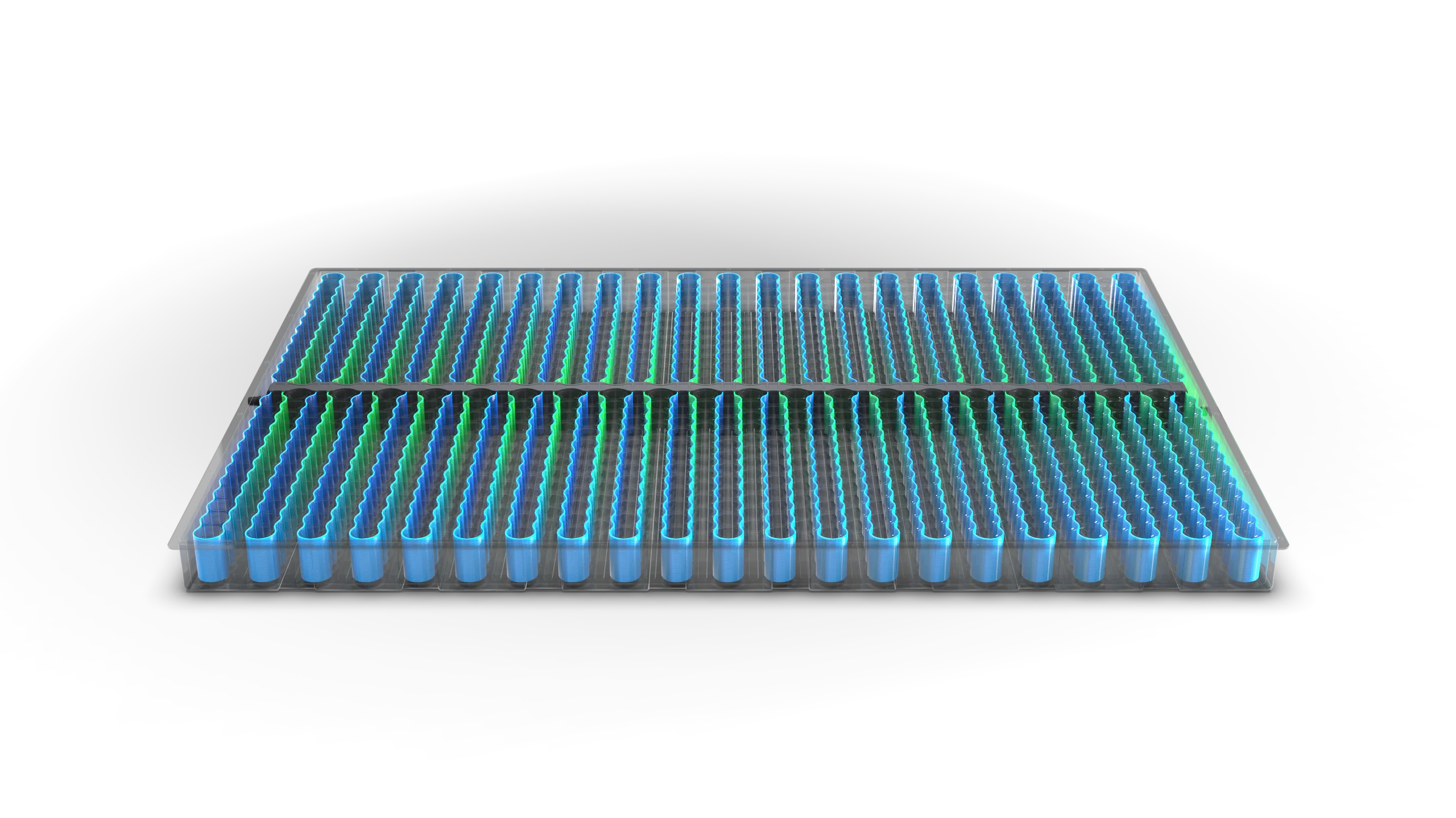

The BTMS-C is the world's first electronically controlled and most advanced heat exchanger, unlocking entirely new possibilities for battery thermal management.

With the BTMS-C, it's now possible to create thermal sections in the battery pack and redistribute the thermal performance between them in real time according to the actual conditions. Now it's possible to concentrate all the thermal performance of the BTMS-C into a single section in the battery pack or create variations of sections with different conditions, e.g. for pre-cooling or post-cooling.

More thermal

performace.

The unique design ensures permanent contact with the battery cells and uniform heat distribution over the entire battery pack. New materials and optimised wall thickness for even more efficient heat exchange.

For applications where battery packs require advanced thermal management, there is the BTMS-C.

Designed

for safety.

The BTMS-C plays a very important role in the Battery Fire Protection System, which significantly contributes to the prevention of thermal runaway.

97% of the BTMS-C is made of electrically non-conductive materials preventing electrical short circuits.

Tech Spec

50/50 %

50/50%

Tube bending radius

Manifold width

> 7 mm

> 14 mm

> 21 mm

> 42 mm

self-extinguishing feature

power cool feature

Chemical

Vibration

Pressure

Corrosion

Great

Great

Good

Great

Good

Poor

Good

Poor

Features

High flexibility ensures permanent contact with each battery cell

Uniform heat distribution

Sectional fluid flow adjustment according to operating condition

We look forward to your iquiry.